Transcoater

Tack Coating For Superior Road Adhesion

Tack coating involves the precise application of a bituminous material to enhance adhesion between an existing road surface and a new asphalt layer. This critical process ensures the durability and longevity of road repairs and new pavements.

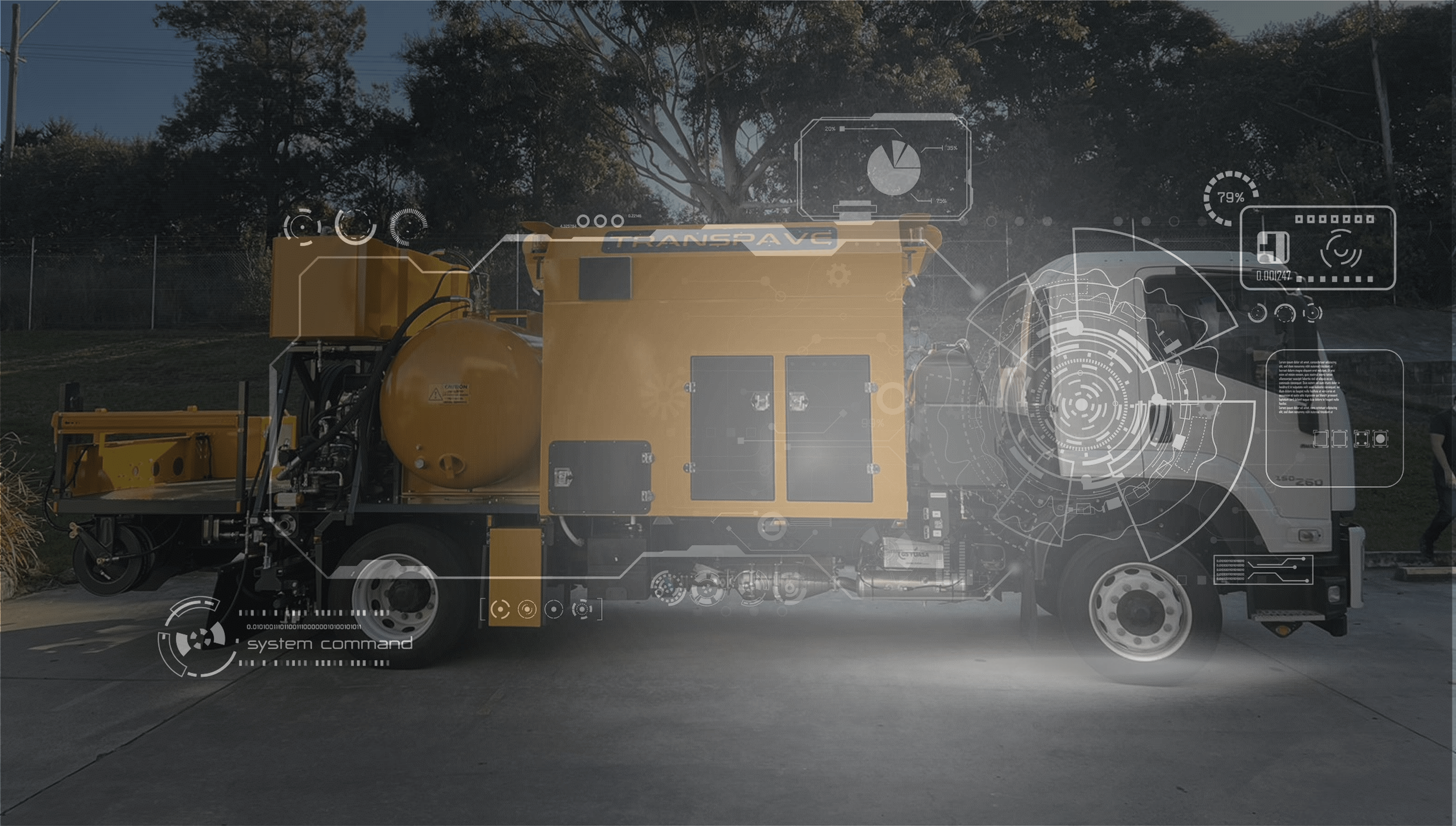

Introducing The TRANSCOATER: Cutting-Edge Technology In Tack Coating

The data-enabled TRANSCOATER has been tested and proven in-field. It offers a suite of advanced features designed to maximise efficiency and reduce waste:

- Auto fill, spray, hand-lance, purge, & vent functions: Streamline operations with automated processes that ensure operator safety.

- Auto pressure regulation: Eliminate trial and error, reducing material waste and improving accuracy.

- Auto bidirectional telescopic spray bars: Enhance coverage range and precision with flexible, in-cab or remote controlled extendable spray bars. The spray bar extends out on both sides of the unit, and features gate control in any combination including in the extensions.

- Auto temperature control: Maintain optimal temperature for bituminous materials, ensuring effective adhesion.

Seamless Connectivity And Asset Management

All TRANSCOATER units are data-enabled, allowing seamless integration with Transpave’s TRANSMIT asset management platform. This connectivity provides real-time data tracking, enhancing maintenance planning and operational efficiency.

Engineered for Function and Budget

TRANSCOATER builds are driven by application - each unit is engineered to suit the operations, equipment preferences, and budget parameters of the end user.

- Chassis-matched design: Configured around the selected truck chassis - crew cab or single cab - ensuring proper fit & function without compromise.

- Specification-led modelling: Weight distribution, tray layout, and functional features are modelled to meet operational requirements, with a design issued for approval prior to build.

- Cost and compliance alignment: Designed within project-specific budget, dimensional, and regulatory limits - without compromising performance or safety.

- In-house engineering and fabrication: Transpave manages the full process from design through to assembly, ensuring quality, consistency, and delivery control.

Why Choose The TRANSCOATER?

Proven reliability

Extensive research, development and in-field testing ensures robust performance.

Innovative technology

Advanced features streamline processes, reduce waste and imporve safety.

Data-driven management

Real-time connectivity with asset management platform enhances traceability and efficiency.

Video can’t be displayed

Virtual Demostration

Comprehensive Repair And Rebuild Services

Transpave not only manufactures advanced tack coating equipment but also offers repair and rebuild services for existing units from other suppliers. Our expert team ensures that all equipment meets high standards of performance and reliability.

Get in Touch

Experience the future of tack coating with the TRANSCOATER. Learn more in our Guide to Purchasing a Tack Coater and contact Transpave today to develop a specification that meets your needs and budget.